Our Services

Why Choose Us?

BEST QUALITY

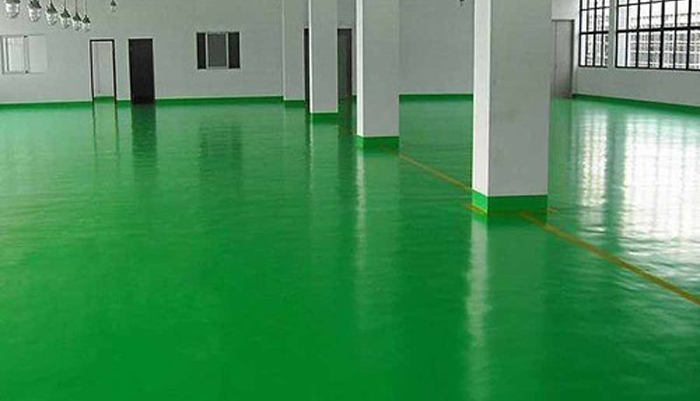

MG Corporation International always maintain our quality work; because we believe that good quality work give to longevity and highly satisfaction. Our all product specification is controlled by the manufacturer because to meet certain basic requirements of our client’s. So, we provides the best Epoxy Flooring & PU Flooring In Bangladesh.

BETTER SERVICE

MG Corporation International resource efficiency is main concerns in our application processes and most importantly we also committed to great standards of sustainability service for all types of products, services and solutions. By the side of the tools and equipment’s for application, we have full of resource with all types of latest items. Our global standard application processes and all time customer support is our motto.

OUR CLIENTS